Since October 2018, we have been milling our maccha in house here at JagaSilk. It has been challenging, always a learning journey, and forever rewarding in terms of flavour, medicinal integrity and relationship building.

The Importance of Fresh Milling

Very early on in JagaSilk’s history, we realized the importance of fresh milling. We noticed that the North American norm of placing a 2 year expiry on tea was not a very transparent system. It was a bit of a shock for us to learn that this date can be based on date of receipt rather than date of production. Though we had decided to put a 9 month expiry on our maccha based on the mill date, we had an unfortunate encounter one day in a grocery store where we happened upon a customer choosing a different company’s maccha because the expiry was further away. Ever since, we moved to a transparent production date (ie. mill date) and haven’t looked back.

The Search for the Right Mill

By focusing on mill dates, it made a lot of sense to start searching for a method of milling in house, but the Japanese requirement for maccha to be less than 10 microns proved an incredibly difficult impasse. The standard granite mill was sitting at $10,000 a unit, and could produce only 40g per hour at its 1 revolution per second; and furthermore, it required refrigeration while in use to keep friction from destroying the fragile umami.

After looking for years, and collaborating with our friend Pedro of o5 Tea in our search, we were able to narrow the mill candidates down to one, a unit produced by an experienced tea equipment manufacturer in Shizuoka Japan. It was superior to ball mills (loud and square in shape), burr mills (we were never able to get down to the right micron size), wind mills (way too expensive) and all other technology we were able to find. It utilised a technology developed domestically to run water through the plates and chill them. They hard plate the stainless steel and have had it cut to mimic the grooves found in the classic granite mills. This produces a particulate shape that is round instead of square, sinking into the pores of the tongue in a way that makes for a smoother texture, and achieves our micron goal at 1kg every 3 hours.

Maccha and Microns

We ensure this particle size by testing using a grain gauge to ensure that it is less than 10 microns. We have found that different cultivars and different regions’ teas mill differently, and that finer isn’t always better. Some selections in our cafe standard category do better with a grind size closer to 9 or 10, while reserve selections in our competition grade categories often do better closer to 7.5. Too coarse at this resolution and you risk sacrificing bitters and depth of flavour for sweetness without backbone. Too fine and the tea can taste rubbery and too bitter. We have also noticed that the flavour straight off of the mill is much more vibrant than even a few days later, so we have learned to mill in a way that isn’t too fine so that we can encourage flavour development in the bag after the fact.

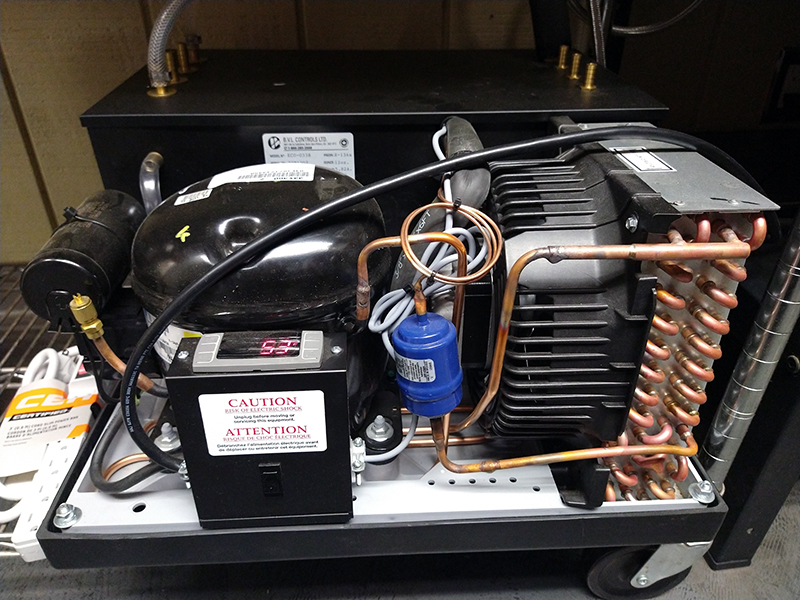

Chilling

More recently we installed a chiller to manage temperature. We had been managing the water temperature to be between 20°C and 30°C by regularly changing the water in the chilling tank and replacing submerged bottles of ice. This kept us very hands on, but made for wide variability. We were finding that in reality, differences of 2°C~3°C were very noticeable. To solve this issue, we worked with a local brewing support company to install this chiller that manages the temperature with much greater resolution. There was a bunch of trial and error to prevent back flow and prevent too much moisture build up, but we are now able to keep the temperature much more stable. There is now the issue where too cold underdevelops flavour, while too hot burns away the umami. Each cultivar and regions’ tea seems to prefer a different temperature for ideal flavour expression. This is a new and uncharted layer for us, and we are excited to start applying different temperatures to different selections.

Learning Opportunities

Milling continues to be an interesting and challenging journey, full of new twists and turns and learning opportunities. New technology, milling fineness, mill temperature, all precede the care we need to take when preparing the tea: weighing, being careful to not use too hot of water, whisking technique; the list goes on. It is the depth of this world that seems to go on forever and ever that makes this all so incredibly interesting and beautiful.

Share this article

Search the blog

JagaSilk Links

Article Categories

Subscribe to our Newsletter

Love maccha? Sign up and get 10% off your first order. You'll also receive new articles and video content!