Over the past several months we have been researching and utilizing the tea roaster we brought in earlier in the year. We started the process with sencha, using aracha (unfired tea meant for sencha) provided to us by Mr. Takaki in Fukuoka Japan. He was a gem and has been incredibly accommodating whenever we visit in showing us his tea roaster in action. He agreed to tune in on his smart phone app to virtually guide us through our first roast, with thoughts on ideal settings and RPM of the roaster, to establish enough contact to cook the tea without burning it. Our first batch we did not turn off the exhaust and just simply could not get the unit hot enough. We figured out that fact in time for the next firing, which we then ran too fast and too short. Unbelievably, perhaps because the raw material from Takaki-san is so amazing, they both taste fantastic.

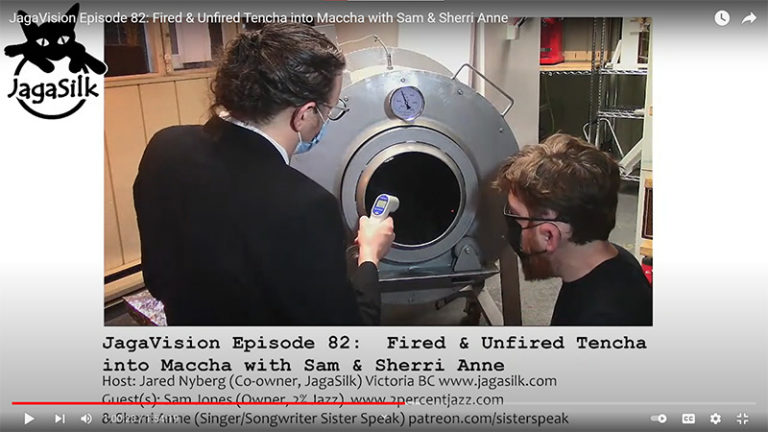

Tencha (the raw material for maccha) had us intimidated. Takaki-san has never fired his own tencha, always leaving that to a local expert factory (though he always fires his own sencha). Borrowing from roast curve dynamics we heard from him and in study for gyokuro, we asked Sam Jones, owner of 2% Jazz Coffee (and one of our earliest clients back in 2005) to join us to fire the first batch of tencha live on JagaVision Episode 82, our weekly livestream, to lend us his insights as a coffee and chocolate roaster. To put this in perspective, we did not even know that finish firing tea was a thing when we started (and rarely see it mentioned in literature), and we were about to embark on firing our very own tencha, the culmination, really, of years of research and curiosity.

“We took a sample at 7.5 mins in at a lower temp, just under 70°C, and cupped it afterward thrilled by the result.”

Our fascination with the process is likely inspired by our years of association with some very talented coffee roasters so it was very meaningful to have Sam join us in what ended up being a shockingly successful first batch. We were convinced it would be a failure the first try. We took a sample at 7.5 mins in at a lower temp, just under 70°C, and cupped it afterward thrilled by the result. At 16m in as we tried to hit our slightly hotter goal, all the aromatics disappeared. We shocked it with 2 minutes of extra heat and it opened up like a flower. The aromatics got buttery and unreal. Milled, this maccha was next level.

Takaki-san only managed to get us 5kg of the Tsuyuhikari single cultivar unfired, but this experience has been transformative and revolutionary for us. Having Sam on gave us the courage to carry the firing to our end goal temp even when getting there felt agonizingly slow. He also suggested some great DIY ideas for cooling that should improve our system and flavour.

We are very excited to start a new chapter here at JagaSilk with our tea roaster. We consider it a point of great meaningfulness that we carefully mill our own maccha here. Moving forward, we will be able to say that our maccha has been both fired and milled in Victoria. There are still so many unknowns. But the success out the gate for flavour has been incredibly encouraging. Without Takaki-san and folks like Sam and our coffee roaster clientelle, I don’t think it would be starting this smooth. From what we have learned though, it will likely get even more challenging as we move forward on this tea firing journey with our tea roaster, and we have immense gratitude that your support allows us to go on this ride.

Share this article

Search the blog

JagaSilk Links

Article Categories

Subscribe to our Newsletter

Love maccha? Sign up and get 10% off your first order. You'll also receive new articles and video content!