When we ferment our kombucha we like to focus on the tea and the honey. The industry norm is to build a canvas and then add flavours in a kind of “shrub”, but we started our program with the idea that good tea will shine through and does well to be the main event.

“We do a 7 day + cold extraction of the tea leaves which brings focus to the fruity and floral flavour components.”

To accentuate this we do a 7 day + cold extraction of the tea leaves which brings focus to the fruity and floral flavour components of the tea leaves (we find hot extractions oxidise the volatile oils in 15 minutes). We then ferment using honey from the Fredrich family in Cedar near Nanaimo as our sugar source. All kombucha ferments need a sugar source and we love that ours is of Vancouver Island and that the raw process highlights so many complexities that would otherwise get lost in pasteurisation. Seasonal variations in consistency, flavour and sugar moisture ratios keep us on our toes and add to the journey of finding that ideal finished brew.

“This “cold crashes” or lagers the yeast and helps to reduce yeast activity in the bottle without having to filter the fermentation.”

We like to ferment our batches for anywhere from 7 to 21 days, all decided by tasting it daily from day 7 until we find an ideal flavour that is reinforced by ideal Brix and pH readings on our measuring tools. We then transfer the batch to a cold tank that drops the temperature we have carefully kept at 20°C down to 3°C. This “cold crashes” or lagers the yeast and helps to reduce yeast activity in the bottle without having to filter the fermentation. The conical bottom of our cold tank collects the yeast for easy blow off. This part kind of reminds me of champagne preparations from historical literature and is loads of fun. The yeasty dregs sometimes taste like guava or pear juice but would make for less shelf stability if we didn’t minimise them.

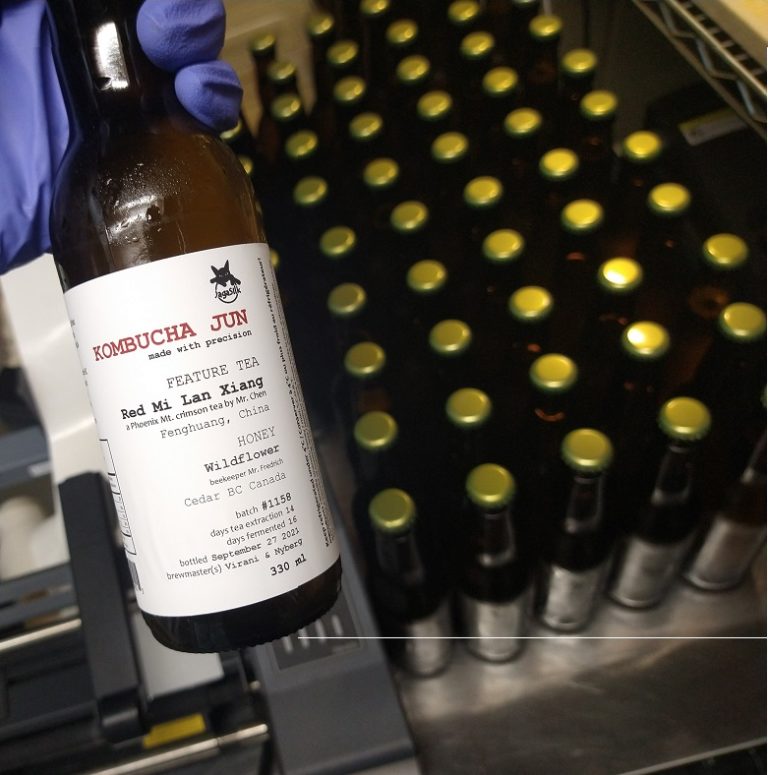

After 3 days minimum in the cold tank we bottle. We use a counter pressure bottle filler and cap with a helpful pneumatic capper. Our label applicator steps up here as well, and with good organization, we can clean, bottle and clean again in under 9 hours for 400 bottles.

We then refrigerate and bottle condition. This is when the yeast eating the sugars and producing carbon dioxide starts to get trapped due to the closed environment and we get natural carbonation. There is nothing like those silky natural bubbles with the carefully cultivated yeast and background careful tea extraction. Conditioning is lovely about a month in, but seems to keep improving and making the flavour dynamics even more complex as the bottles age. It is important not to leave the bottles out of the fridge or temperatures above 4°C, as the CO2 starts to congregate out of solution and can foam out of the bottle when opened. Cold temperatures submerge the CO2 in the liquid and make for that gorgeous effervescence.

It’s hard to believe the program started with 12 bottles brewed weekly in 2 gallon glass jars. But we track each and every batch with good record keeping, and our 1158th batch is tasting very promising indeed. Every batch, every month, is a fascinating exploration of the universe of fermentation.

Share this article

Search the blog

JagaSilk Links

Article Categories

Subscribe to our Newsletter

Love maccha? Sign up and get 10% off your first order. You'll also receive new articles and video content!